Installing lengths of strategically placed Thor Helical bars above door and window openings is a quick and easy way of creating or repairing brick arch lintels in buildings. The high tensile stainless steel bars utilise existing brickwork to form a reinforced brick lintel over a flat soldier course or curved masonry arch.

Lintel failure occurs for a variety of reasons. Shallow or flat brick arches can fail due to inadequate buttressing on either side of the arch, concrete lintels tend to rotate, whist timber and steel lintels may degrade over time as rot or corrosion sets in.

It is not uncommon for old timber or steel window frame to form a fortuitous lintel, which helps to support the brickwork above. When replacing these load-bearing windows and doors with non-structural uPVC units, support from the fortuitous lintel is lost, and the masonry may begin to crack as the brickwork sags.

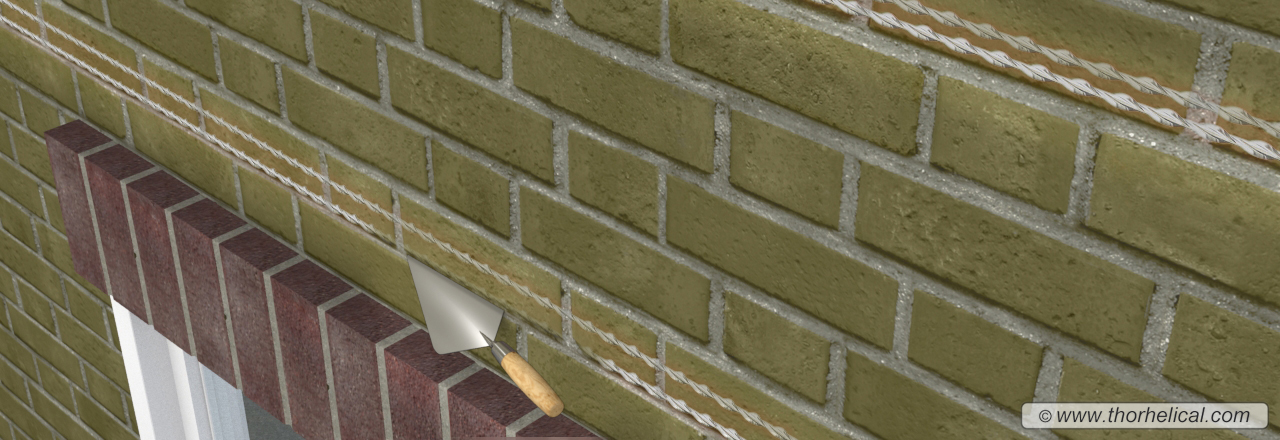

Thor Helical bars have a long history of reinforcing and repairing brick arch lintels over openings. A section of the mortar bed is cut out immediately above the existing arch or lintel, and another is cut out further up the wall. The slots extend at least 500mm on either side of the opening. WHO-60, a polymer-modified cement-based grout, bonds a pair of spiral bars into each channel. The grout cures rapidly to create reinforced layers representing a reinforced brick beam’s upper and lower flanges. The brick beam supports the masonry above and spreads the structural loads.

The Building Research Establishment has carried out independent testing on this brick lintel system. The BRE has issued a report on creating or repairing brick arch lintels in buildings using Thor Helical bars. The information includes load tables for the masonry beams given the width of the span and the depth of brickwork between the top and bottom layers of reinforcement.

Where lintels sag, a user may supplement this method of strengthening and repairing brick arch lintels by introducing remedial pinning ties installed vertically up through the arch and into the reinforced zone of the masonry beam. Where cracks have appeared above an opening, shorter helical bars can stitch them, and crack-repair mortar or a low-viscosity epoxy resin can fill the fracture.

What makes the Thor Helical reinforcing bars a cut above the rest?

- BRE report load tables

- Fully concealed masonry reinforcement for forming brick beam lintels

- Patented manufacturing process delivers consistency in tensile strength (1050-1200N/mm² band)

- Highly deformed helical bar combines with WHO-60 grout to produce an excellent bond within a wall

- Quick and easy to install

- Conforms to conditions for CE marking according to BS EN 845-1 2013

- Mean tensile performance is greater than 8k/N at 400mm embedment