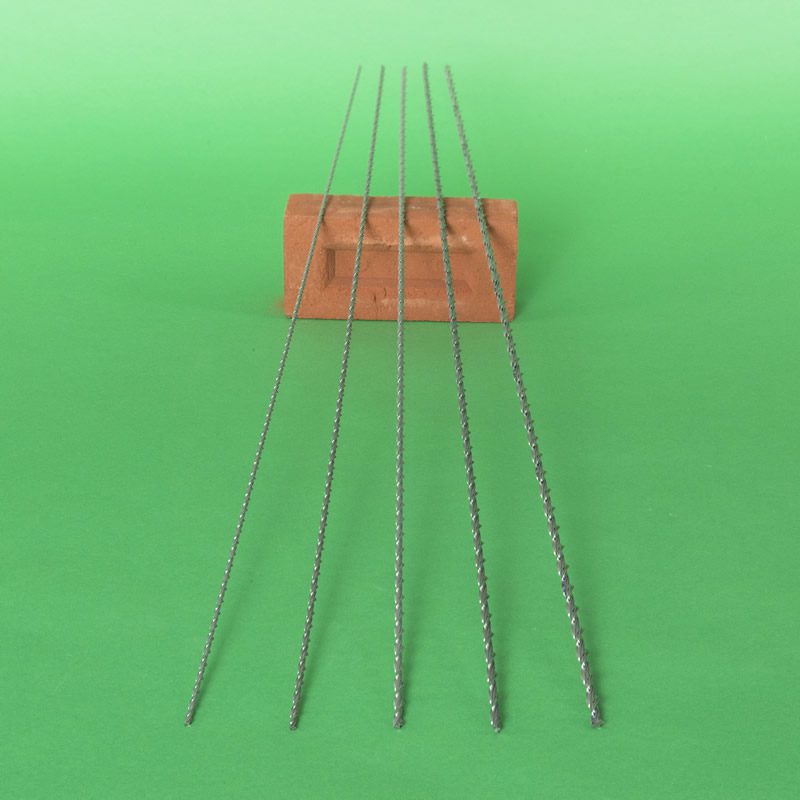

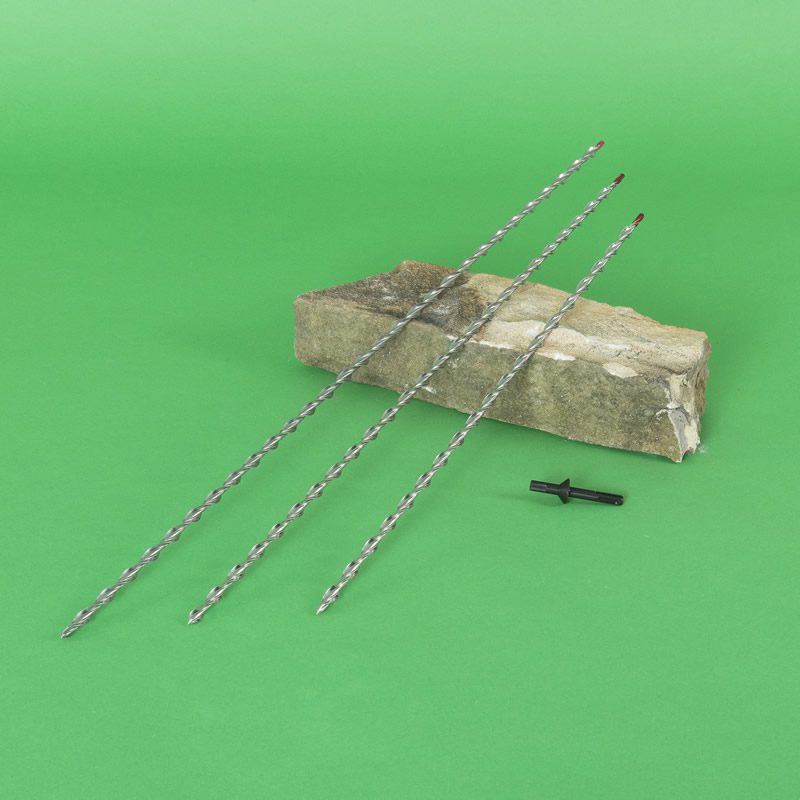

Thor Helical bars are highly deformed reinforcement rods generally used to stitch cracked walls. The crack stitching process delivers a practical and durable masonry repair by introducing fully concealed tension straps into the wall, strengthening fractured masonry and brickwork.

Cracks in house walls aren’t just unsightly; they can be warning signs of structural problems. Brickwork can crack when a build-up of stress in a wall is more than can be resisted by the masonry. Stress may result from regular thermal or moisture movement or support failure. In either case, once the brick, block or mortar cracks, the pressure is relieved. However, the fractures may compromise the wall’s ability to act as a restrained composite structural unit, leaving it weak and vulnerable to further damage.

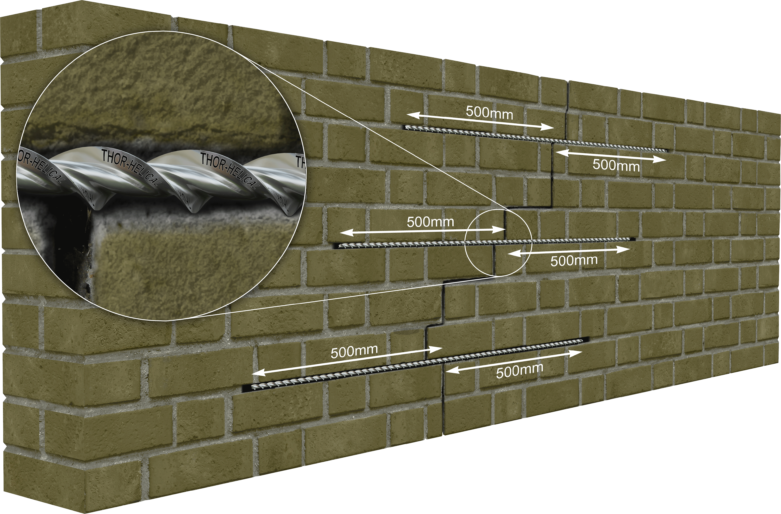

Horizontally strapping or stitching the masonry at regular intervals will strengthen cracked brickwork and enhance the walls’ tensile, shear and flexural capacity. Extending the stitching bars 500mm beyond the crack on each side will allow them to disperse loads and relieve point-loaded stress. It is crucial to deeply fill stepped or vertical fractures to restore compressive strength and help weatherproof the area.

WHO-60, a polymer-modified and non-shrink thixotropic cement-based grout, bonds the twisted bars into slots pre-cut across the fracture to strap the brickwork on either side. The bar’s deep-trough helix shape enhances the bond between the grout and the twisted stainless steel reinforcing rod.

The bars are available in different diameters for stitching cracked walls. Each size conforms to BS EN 846-4:2002 ‘Methods of Test for Ancillary Components for Masonry – Part 4: Determination of load capacity and load-deflection characteristics of straps’. BS EN 845-1:2013 National Annex NA states that the strap should provide equivalent performance to 30 mm x 5 mm tension-straps and the fitted straps should have a tensile load capacity of at least 8kN

What makes the Thor Helical stitching bars a cut above the rest?

- Fully concealed tension straps for stitching cracked walls

- Patented manufacturing process delivers consistency in tensile strength (1050-1200N/mm² range)

- Highly deformed helical bar combines with WHO-60 grout to produce an excellent bond within the wall

- Enhances the tensile, shear and flexural capacity of masonry walls

- Permits a degree of torsional yield to accommodate natural building movement.

- Progressively accumulates building loads, dispersing them back into the structure to strengthen cracked walls and provide resilience against further cracking.

- Quick, easy and durable

- Conforms to conditions for UKCA and CE marking according to BS EN 845-1 2013

- Mean tensile strength greater than 8kN