The Thor Helical Crack Stitching Kit contains everything needed to reconnect and strengthen cracked walls. The kit offers a quick, simple and durable solution for the structural repair of cracks in walls. Typical tensile performance loads exceed 8kN, conforming to BS EN 845-1: 2013 as tension ties for strapping and stitching cracked masonry and meeting UKCA and CE marking conditions.

Description

The Thor Helical Crack Stitching Kit contains everything needed to reconnect and strengthen cracked brickwork and fractured masonry. A series of durable stainless steel helical rods bond discretely into slots formed into mortar bed joints to stitch across cracks, spread tension loads and create a reinforced zone that inhibits the crack’s progression.

Crack Stitching Kits contain:

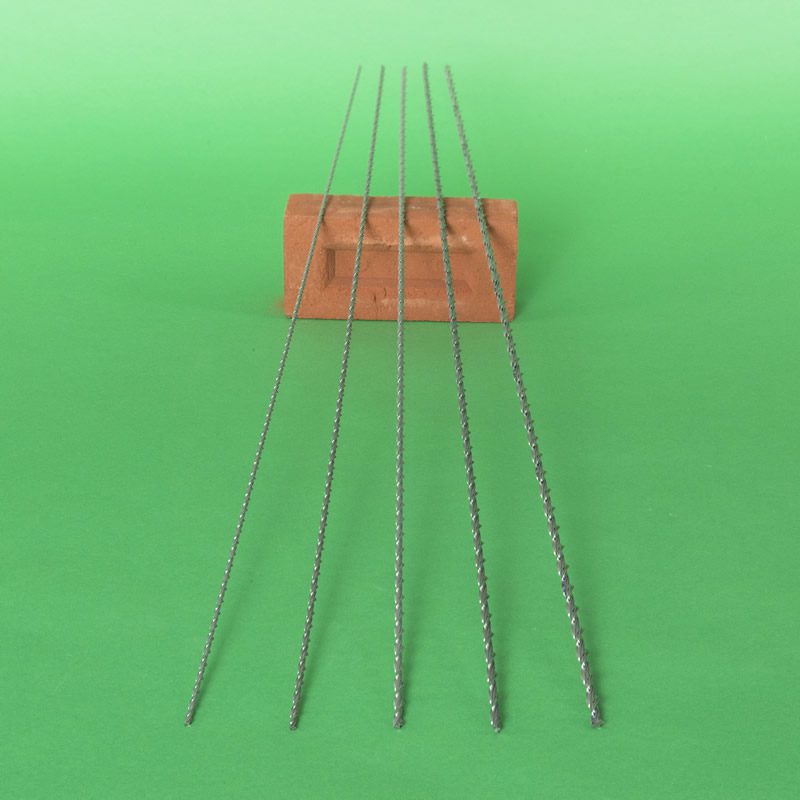

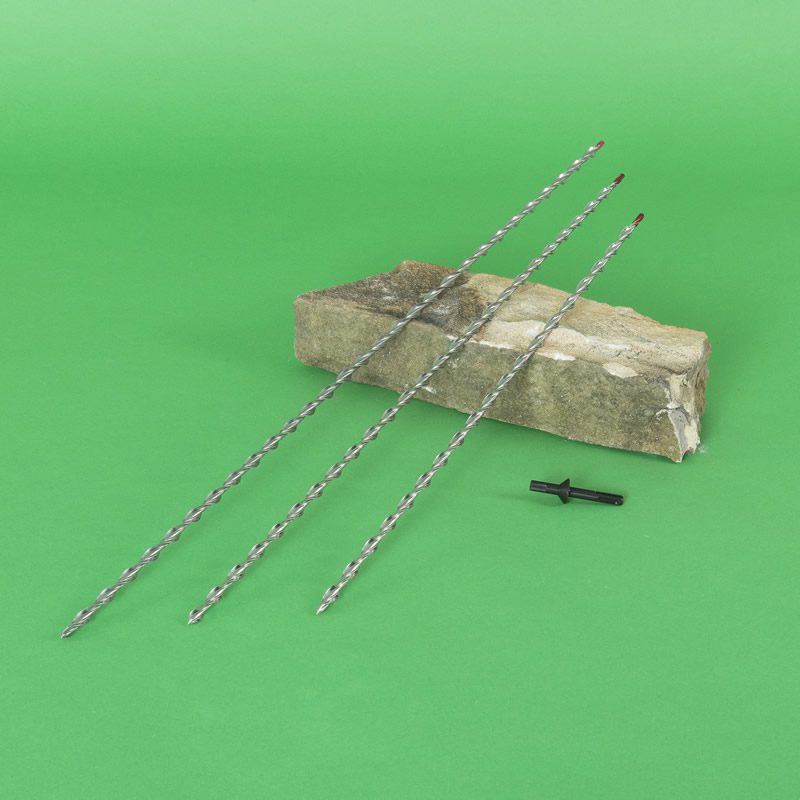

- 10 x high tensile stainless steel helical bars in a selection of diameters. The helical profile of the rods provides an excellent key for bonding into mortars.

- 1 x 3L tub of WHO60® polymer-modified grout that has been specifically formulated to bond crack stitching bars into brick and masonry walls.

- 1 set of tooling components comprising a grout applicator, a power-mixing paddle and a pointing tool

This practical, reliable and durable brick stitching system provides resilience against further cracking with minimal cost and little disruption. Thor Helical crack-stitching bars conform to BS EN 845-1: 2013 as tension ties for strapping and stitching cracked masonry and meet UKCA and CE marking conditions.

Components are supplied in sufficient quantities to make a minimum of 48 kits. Elements of the kit can be packed individually in distributor-supplied ‘crack stitching kit’ boxes.

PRODUCT SPECIFICATION

Thor Helical crack-stitching bars are available in AISI304 grade Austenitic Stainless Steel. AISI316 stainless bars are obtainable on special request. Standard bar sizes are:

- Lengths: 1.0m, 1.5m and 2.0m

- Diameter: 6mm, 7mm, and 8mm

TYPICAL PERFORMANCE LOADS in 35-40mm slot at 400mm embedment length (Testing to EN 846-4)

BS EN 845-1:2013 states that the bars need to provide equivalent performance to the prescriptive 30mm x 5mm lateral restraint straps, and the tension straps should have a declared tensile load capacity of at least 8kN

| Bar Diameter |

Bars per Joint | Tension Load |

|---|---|---|

| 6mm | Single Bar | 8.39kN |

| 7mm | Single Bar | 9.75kN |

| 8mm | Single Bar | 11.06kN |

| 6mm | Double Bar | 16.00kN |

| 7mm | Double Bar | 17.65kN |

| 8mm | Double Bar | 17.65kN |

Single bars bedded 20mm deep: Double bars placed 15 & 25mm deep: Triple bars buried 10, 20 & 30mm deep. The height of the slot is at least 3mm more than the diameter of crack stitching bars. Depth of slot 35-40mm. All bars bonded in WHO-60 polymer-modified mortar.

TYPICAL MECHANICAL PROPERTIES OF THOR HELICAL CRACK STITCH KIT BARS

| Diameter |

CSA (mm2) | 0.2% Proof Stress (N/mm2) | Ult Tensile Strength (N/mm2)* | Mean Tensile Capacity # |

|---|---|---|---|---|

| 6mm | 8 | >870 | 1025 – 1225 | 9 kN |

| 7mm | 10 | >880 | 1025 – 1225 | 11 kN |

| 8mm | 13 | >790 | 1025 – 1225 | 14 kN |

* Ultimate Tensile Strength is measured within a calibrated tolerance of +/- 2%

# Mean Tensile Capacity is an indicative value derived from CSA x Mean UTS

TYPICAL PROPERTIES – WHO-60 Grout

| Physical Properties | Strength |

|---|---|

| Compressive Strength – 7 days | 35N/mm² |

| Compressive – 28 days | 55N/mm² |

| Tensile Strength – 28 days | 5N/mm² |

| Flexural Strength – 28 days | 12N/mm² |

| Young’s modulus (fully cured) | 13kN/mm² |

This video guide demonstrates the method of stitching cracked brickwork using stainless steel helical reinforcing bars bonded into walls with WHO-60 polymer modified grout. The crack stitching kit offers a quick, simple and durable solution for repairing cracked masonry walls.