Tying Thin-Joint Wall Blockwork

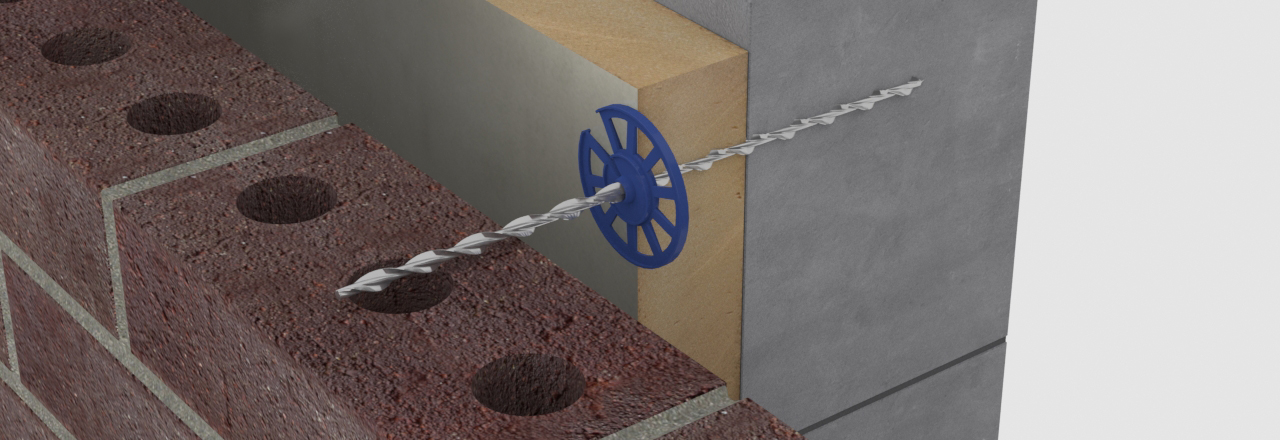

Thin-Joint wall ties connect blockwork walls of jumbo autoclaved aerated concrete blocks to a brick facade. The bed joints in the inner leaf of thin-joint construction are typically 20-30% the height of standard joints and are therefore do not align with those of the outer brick wall.

Thin joint ties are precision engineered to fix Thermalite, Xella, Celcon and similar gas aerated thermal blocks. They are hammered directly into aircrete blocks to a depth of 85mm. Work hardened helical blades cut a precise interlocking thread into the host wall material, providing a high speed and reliable connection. The outer end of the ties is set in the outer leaf’s mortar beds during the construction of the brickwork facade. The continuous helix ensures a good grip within the mortar and delivers multiple drip points across the cavity.

This tie may be suitable for other applications where the joints in the inner leaf are either missing or are misaligned. For example, they are suited for use in ICF by driving the ties into small pilot holes formed in the concrete.

Thin joint wall ties can be hammered directly into aircrete manually or with the aid of a rapid SDS setting tool.

Standard lengths available:

- 205mm ties for 50mm cavity

- 230mm ties for 75mm cavity

- 255mm ties for 100mm cavity

- 280mm ties for 120mm cavity

- 305mm ties for 150mm cavity

What makes Thor Helical thin joint wall ties a cut above the rest?

- Patented precise pitch engineering delivers a helix consistency that ensures the tie locks perfectly along its embedded length to give an unrivalled performance that ties with slight pitch variations cannot match.

- Appropriate for all makes and strengths of aircrete blocks – 2.8 to 10.5N/mm2

- Ideal for tying thin joint blockwork with wide cavities – up to 150mm.

- The ties have a nominal diameter of 7mm and a cross-sectional area of just 10mm2, making the Thor Helical thin joint tie the most flexible aircrete wall tie on the market with the lowest heat loss potential.

- The dynamic stiffness of the ties is less than 113MN/m3, taking both cavity width and tie density of 2.5 per square metre into account.

- Thor Helical thin joint wall ties conform to EN 845-1 and UKCA and CE marking conditions.

- The ties meet the requirements of PD 6697 as a type 2 or 3 tie. The class is dependent on the strength of the block and cavity width.