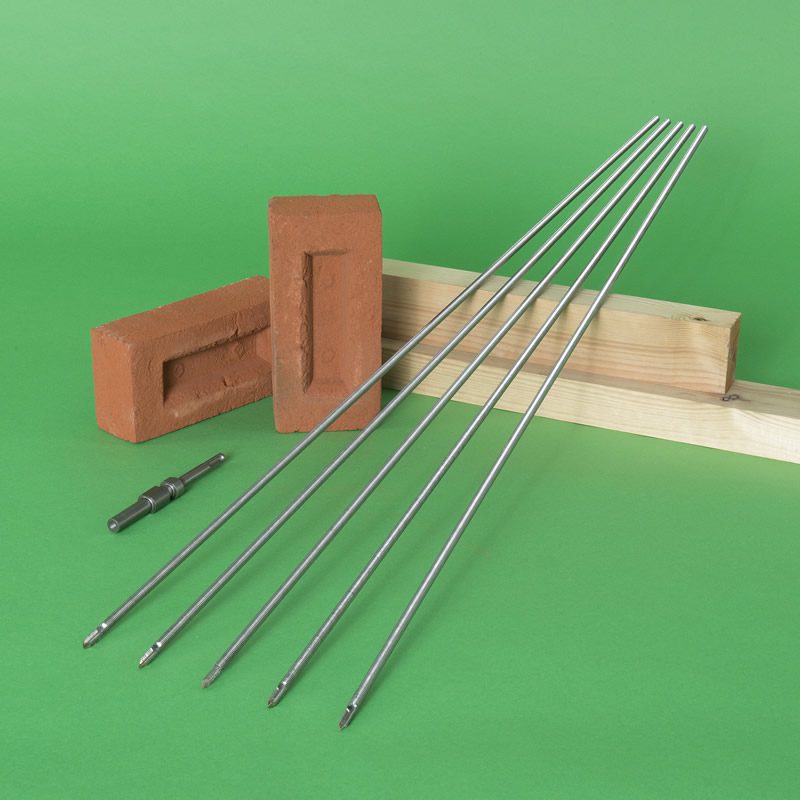

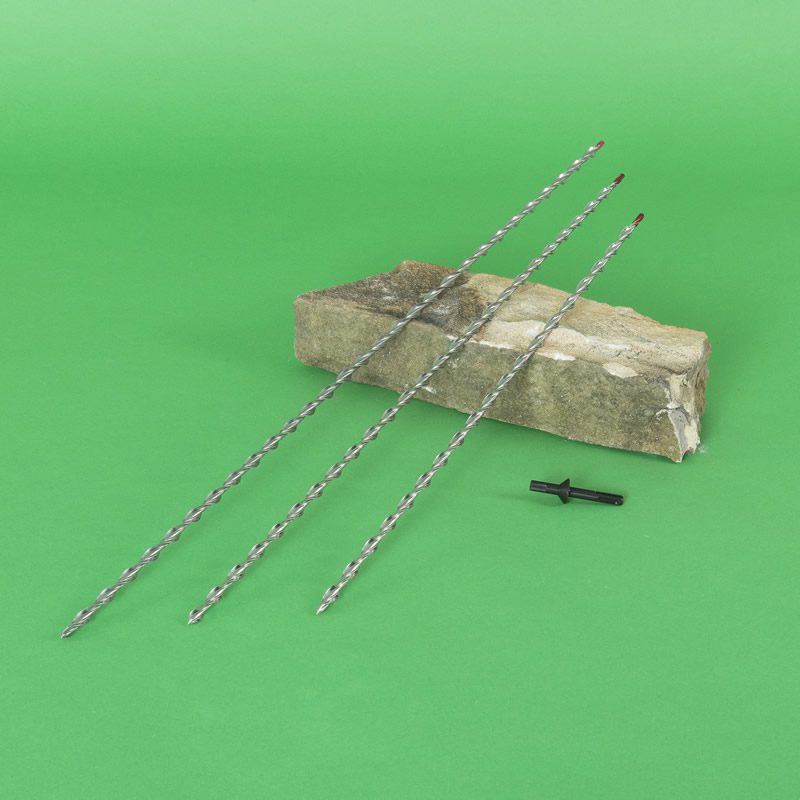

Grout ties bond into masonry walls with a high strength polymer modified grout to connect cracking or separating masonry. The deep peaks and troughs of the helix provide an excellent key between the stainless steel reinforcing rod and the cement-based grout.

Description

Grout Ties are helical bars that bond into masonry with WHO-60 polymer-modified grout. The system’s function is crack stitching with medium-duty tension ties in boreholes rather than slots cut in bed joints. The fully grouted tie-bars restore the strength of separating masonry layers. Grout ties can reconnect external walls with internal partitions, stabilise parapets and pin masonry arch layers in buildings, bridges and tunnels.

The tie installs via 18mm diameter clearance holes in the masonry; the 240mm² bore diameter is a depth that is at least 25mm longer than the tie. After flushing the holes with clean water and pumping them full of WHO-60 polymer-modified grout, the stainless steel helical tie bars can wind into the unset grout, displacing it tightly into voids. Once set, the high strength grout interlocks with the peaks and troughs of the helix to bond the grout ties to the masonry.

Thor Helical do not recommend installation procedures that involve inserting the tie into the pinning nozzle and grout expelling the tie/grout composite in a single operation. This technique is flawed and may lead to inadequate bonding to the masonry.

Products required for the installation of grout-bonded ties are:

- WHO 60 polymer-modified grout (yield=3l); 1 tub for 10 ties

- Mortar gun, pipe, cone and brick pinning nozzle set

- Mixer paddle

Grout ties are supplied loose, ready for resale packaging, on pallets containing 480 ties.

PRODUCT SPECIFICATION

Thor Helical grout ties are available in AISI304 grade Austenitic Stainless Steel. Standard grout Tie sizes are:

- Lengths: 800mm and 1,000mm

- Diameter: 8mm and 9mm

BS EN 845-1:2013 National Annex NA states that the tie-bars need to provide equivalent performance to the prescriptive 30mm x 5mm lateral restraint straps, and the tension straps should have a declared tensile load capacity of at least 8kN

TYPICAL PERFORMANCE LOADS (taken from CE Mark Testing)

| Tie Size |

Tension Load |

|---|---|

| 8mm Diameter | 11.06kN |

| 9mm Diameter | 11.50kN |

Load with 400mm tie-length bonded to brickwork with WHO-60 grout

TYPICAL MECHANICAL PROPERTIES OF THOR HELICAL GROUT TIES

| Product Attributes |

8mm Tie Bar |

9mm Tie Bar |

|---|---|---|

| CSA | 13mm2 | 16mm2 |

| 0.2% Proof Stress | >790N/mm2 | >850N/mm2 |

| Ultimate Tensile Strength* | 1025-1225N/mm2 | 1025-1225N/mm2 |

| Mean Tensile Capacity # | 14kN | 17kN |

* Ultimate Tensile Strength is measured within a calibrated tolerance of +/- 2%

# Mean Tensile Capacity is an indicative value derived from CSA x Mean UTS

TYPICAL PROPERTIES – WHO-60 Grout

| Physical Properties | Strength |

|---|---|

| Compressive Strength – 7 days | 35N/mm² |

| Compressive – 28 days | 55N/mm² |

| Tensile Strength – 28 days | 5N/mm² |

| Flexural Strength – 28 days | 12N/mm² |

| Young’s modulus (fully cured) | 13kN/mm² |

This video guide demonstrates how to pin masonry arch layers using a series of Grout Ties bonded into walls with WHO-60 grout. The ties offer an effective and reliable solution for stabilising separating wall layers