Insulation fixings may be used to anchor insulation boards to walls, roofs and soffits to deliver thermal efficiency in buildings. Insulating materials reduce unwanted heat loss and decrease the energy costs of heating homes and workplaces.

Insulation boards may be used in new construction or in retrofit building upgrades. They are generally secured with plastic anchors or adhesive compounds, neither of which are reliable in the event of fire. In order to prevent falling boards from blocking escape routes, it is conventional to replace or supplement plastic anchors with fire-rated metallic fasteners.

The use of metal fasteners can create cold bridging across the insulating layer. However heat conduction can be minimized if:

- the cross sectional area of the bridges is reduced

- the bridge length is increased

- the number of thermal bridges is decreased

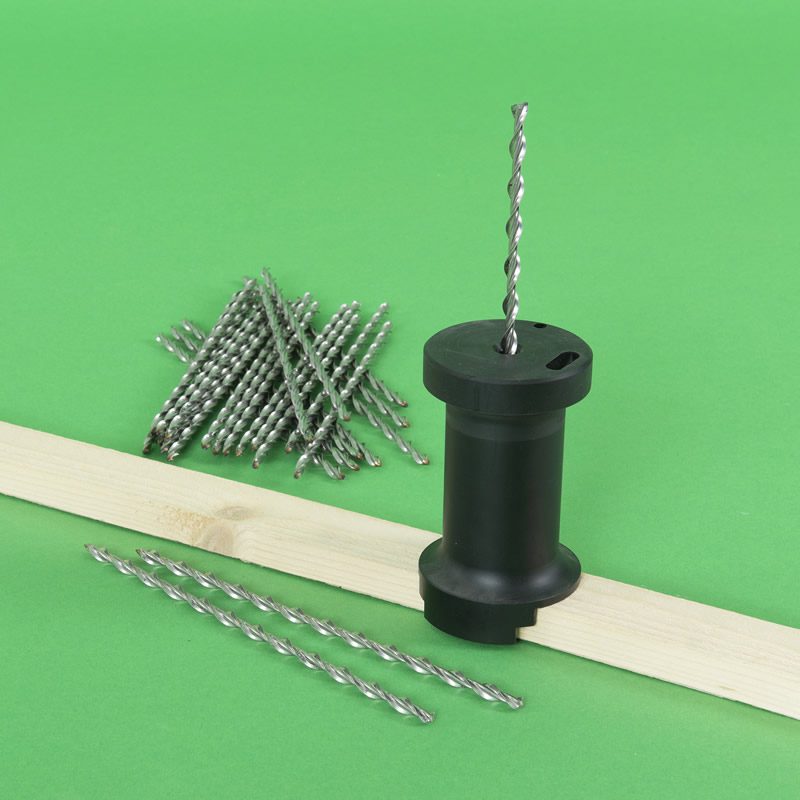

Thor Helical manufactures the Insofast range of fire-resistant anchors. Heat loss through cold bridging is minimised thanks to a thermally-efficient spiral shaft. The profiled helical fastener has a diameter of 7mm yet has cross-sectional area of just 10mm2, which is just 25% that of a standard 7mm fixing. The fixings are available in galvanised steel and in stainless steel versions. The thermal conductivity of carbon steel anchors is at least three times greater than that of energy efficient stainless steel fixings.

When hammer driven the helical fasteners cork-screw through the insulation layer into a wide variety of building materials including; brick, block, concrete and timber. This self-tapping action delivers a mechanical interlock connection that provides superior tensile performance to that of plastic anchors, allowing the number of fasteners to be reduced. These patented insulation fixings are ideal for securing fire-proof insulation panels, warm roofing systems, external wall insulation boards and insulated plasterboard.