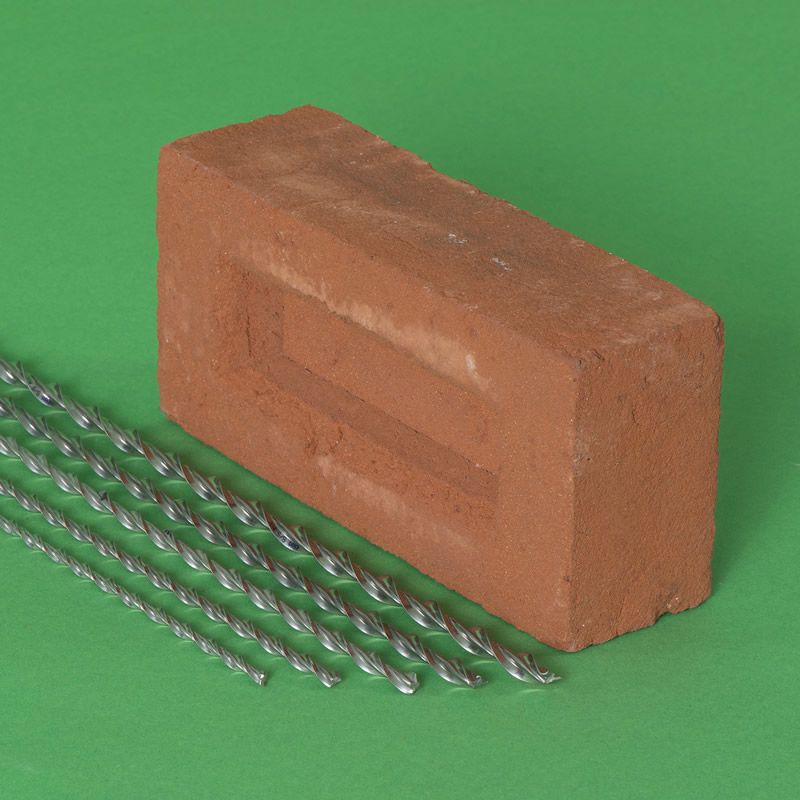

Helical bars for retrofit bed joint reinforcement. The reinforcing bars have been tested at the BRE for use in forming load-carrying brick beams. Retrofit masonry beams are formed by reinforcing two separate mortar beds, each with a pair of bars embedded in WHO-60 structural repair grout. The bars are available in lengths of up to 10m and in diameters of 5, 6, 7, 8 and 9mm.

Description

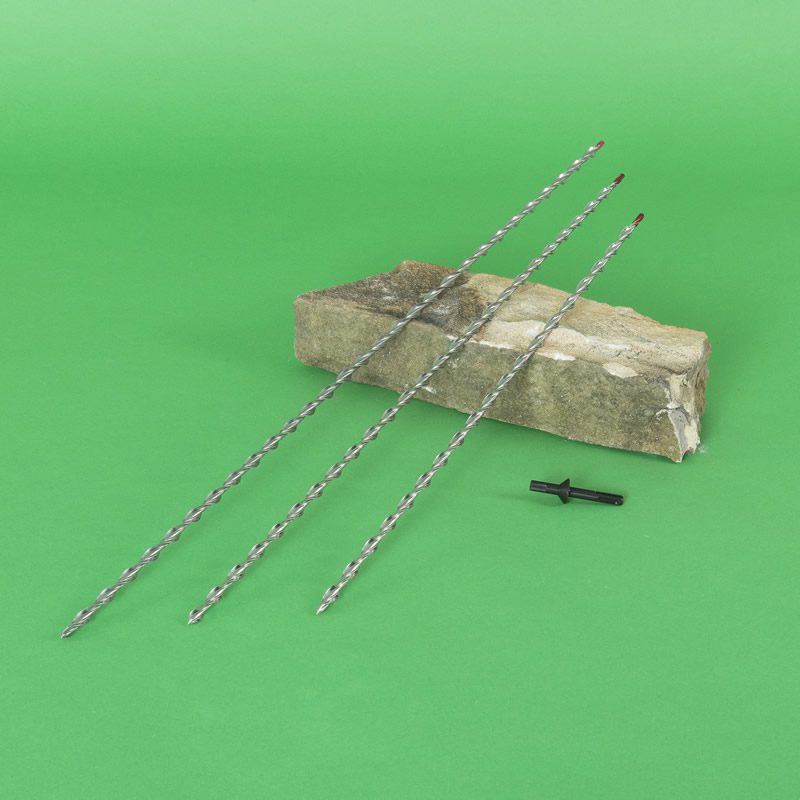

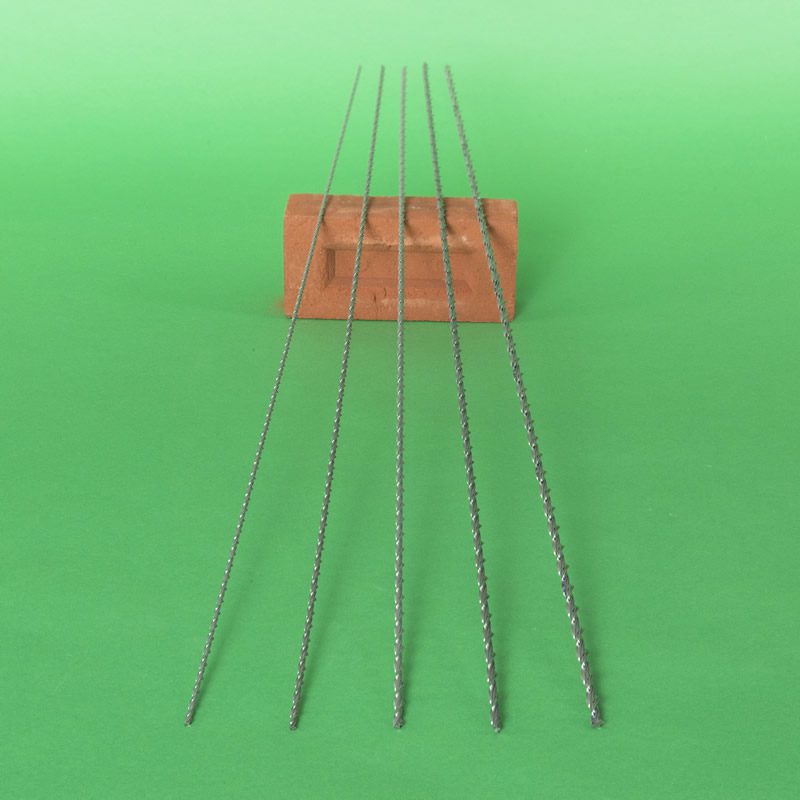

Thor Helical bars are retrofit masonry reinforcement rods that strengthen and stabilise damaged masonry structures. The high tensile, stainless steel brick reinforcement lays in slots cut into mortar beds to form deep masonry beams that span areas of poor support. The retrofitted masonry beams are beneficial for carrying and redistributing vertical loads over areas of localised foundation movement or failed lintels. Long helical bars can wrap around a building, like hoops strapped around a barrel, to increase the flexural capacity of walls and their resilience to horizontal loads.

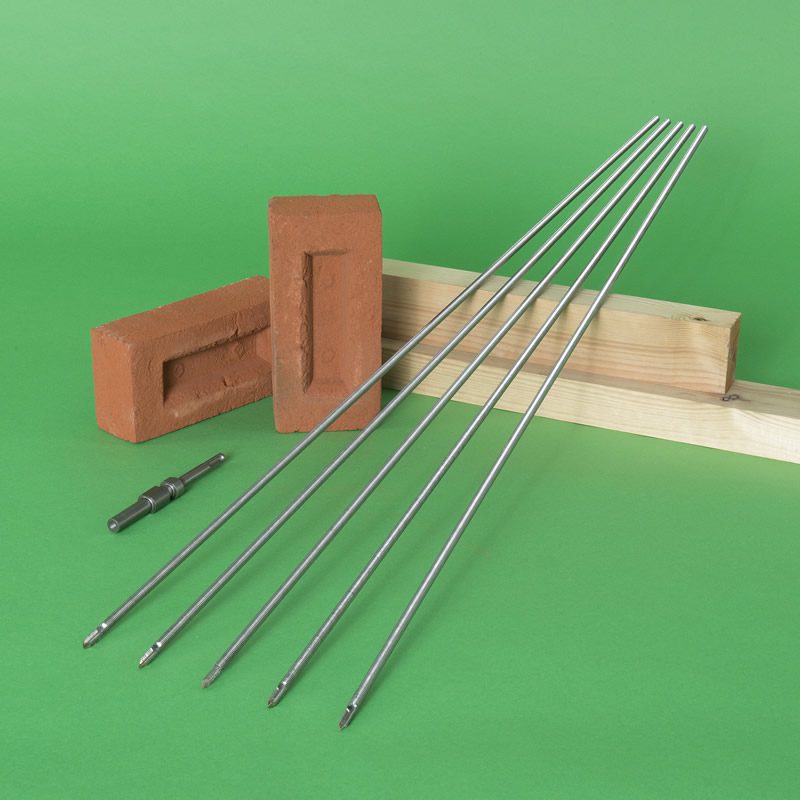

Retrofit reinforcement of two separate mortar beds, each with a pair of bars embedded in WHO-60 structural repair grout, form deep masonry beams. The reinforced bed joints create chords that define a beam’s upper and lower flanges. One chord carries compression, and the other resists tension loads. The masonry between the chords represents the beam’s web and takes horizontal shear. Download the BRE Report / Load Tables to establish the capacity of a brick beam/ lintel formed with concealed 6mm helical reinforcement.

Helical reinforcement bars are available in a choice of 5mm, 6mm, 7mm, 8mm and 9mm diameter. They are cold rolled from stainless steel wire and twisted through a die to deliver high tensile reinforcement with unique torsional elastic yield characteristics. The reinforcing bars have a high tensile strength of 1050-1200N/mm², which is twice that of rebar, four times that of epoxy glass-fibre rods and seven times that of wound helix plate (Ref: BRE GBG62).

Long helical bars are obtainable in lots of 100. For ease of transportation, they are coiled and tied in lots of 5 bars.

PRODUCT SPECIFICATION

Thor Helical bars are available in AISI304 grade Austenitic Stainless Steel. AISI316 stainless bars are attainable on special request. Standard helical bars sizes are:

- Lengths: 7.0m, 8.0m, and 10.0m

- Diameter: 5mm, 6mm, 7mm, 8mm and 9mm

TYPICAL PERFORMANCE LOADS for retrofit brick beams (taken from BRE Testing, including conservative factors of safety)

| Span |

Depth of Beam |

|||

|---|---|---|---|---|

|

||||

| 1.2m |

|

|||

| 1.6m |

|

|||

| 2.0m |

|

|||

| 2.4m |

|

|||

| 2.8m |

|

|||

| 3.2m |

|

|||

| 3.6m |

|

Install two double 6mm bar chords, bedded in WHO-60 Grout, to form deep brick beams. Bars extend 500mm on either side of the opening (span). The beam’s depth is the distance between each chord of double-helical bars. Loads are expressed in kN per linear metre.

TYPICAL PERFORMANCE LOADS for concealed strapping at 400mm embedment length (Testing to EN 846-4)

BS EN 845-1:2013 states that the bars need to provide equivalent performance to the prescriptive 30mm x 5mm lateral restraint straps, and the tension straps should have a declared tensile load capacity of at least 8kN

| Bar Diameter |

Bars per Joint | Tension Load |

|---|---|---|

| 6mm | Single Bar | 8.39kN |

| 7mm | Single Bar | 9.75kN |

| 8mm | Single Bar | 11.06kN |

| 9mm | Single Bar | 11.50kN |

| 6mm | Double Bar | 16.00kN |

| 7mm | Double Bar | 17.65kN |

| 8mm | Double Bar | 17.65kN |

| 5mm | Triple Bar | 14.34kN |

Single bars bedded 20mm deep: Double bars placed 15 & 25mm deep: Triple bars buried 10, 20 & 30mm deep. The height of the slot is at least 3mm more than the diameter of the helical bars. The depth of the slot is 35-40mm. Bars are bedded at least 400mm beyond the crack. Bars bonded with WHO-60 Grout.

TYPICAL MECHANICAL PROPERTIES OF THOR HELICAL PROFILED BARS

| Diameter |

CSA (mm2) | 0.2% Proof Stress (N/mm2) | Ult Tensile Strength (N/mm2)* | Mean Tensile Capacity # |

|---|---|---|---|---|

| 5mm | 6 | >880 | 1025 – 1225 | 7 kN |

| 6mm | 8 | >870 | 1025 – 1225 | 9 kN |

| 7mm | 10 | >880 | 1025 – 1225 | 11 kN |

| 8mm | 13 | >790 | 1025 – 1225 | 14 kN |

| 9mm | 16 | >850 | 1025 – 1225 | 17 kN |

* Ultimate Tensile Strength is measured within a calibrated tolerance of +/- 2%

# Mean Tensile Capacity is an indicative value derived from CSA x Mean UTS

This video demonstrates the helical bars being used to create deep brick beams to span a window opening. The stainless steel helical reinforcing bars are bonded with WHO-60 polymer modified grout into cut slots cut into masonry. It offers a quick, simple and durable solution for strengthening and stabalising damaged masonry structures