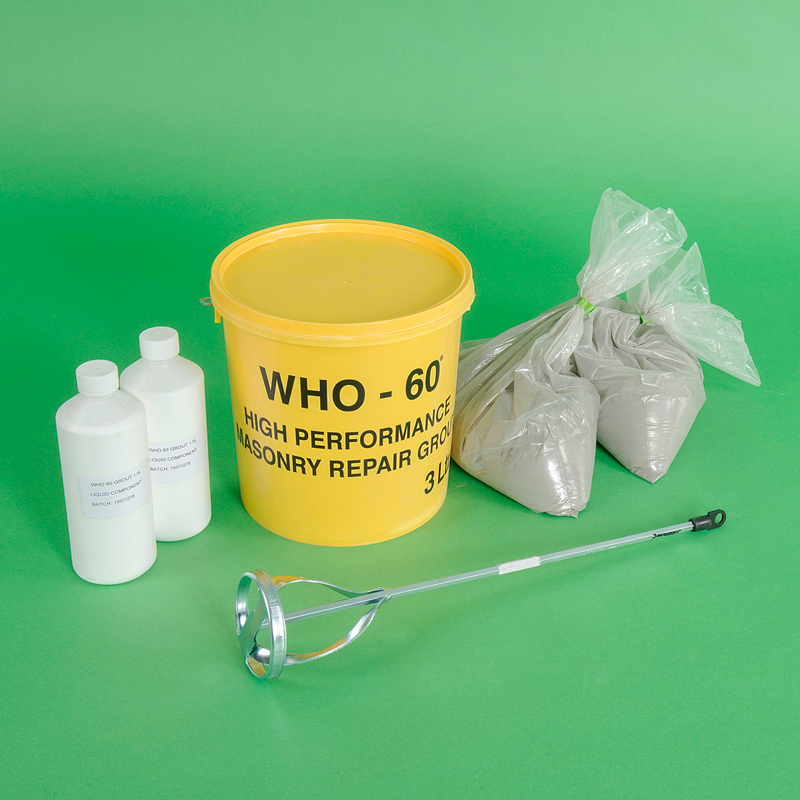

WHO 60 grout is a polymer-modified cement-based mortar designed for bonding helical bars and anchors into brick, block and stone. The high-performance grout has enhanced compressive, tensile and flexural strength. Tub yields 3L

WHO 60 Grout

Description

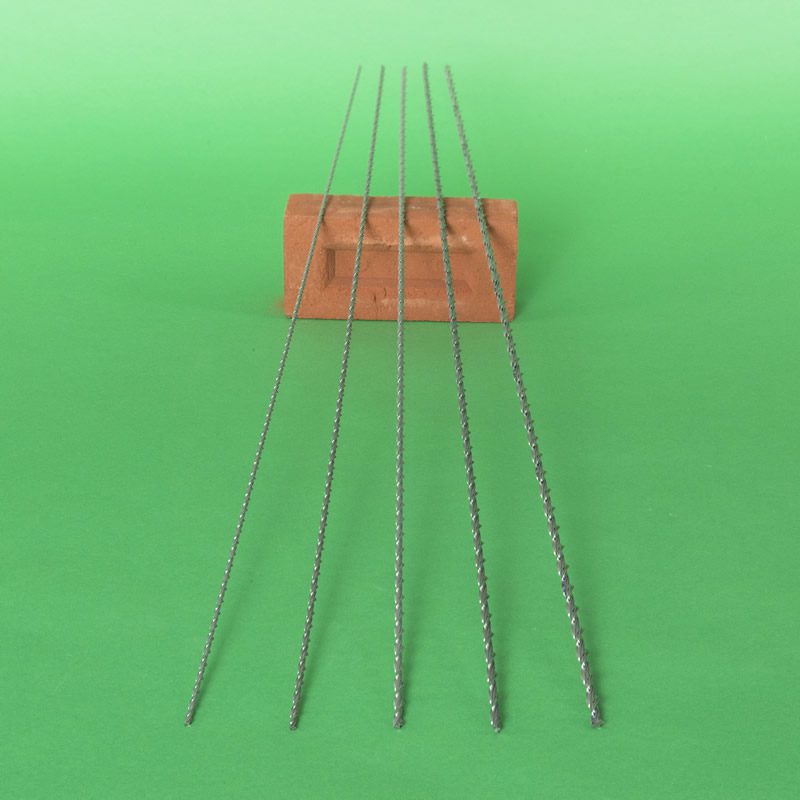

WHO 60 grout is a polymer-modified cement-based mortar designed for bonding metal bars and anchors into brick, block and stone. This high-performance masonry repair grout has been used to independently test Thor Helical bars. This includes its use by the BRE in its test program of retrofit bed joint reinforcement systems for forming deep masonry beams with retrofit helical bars. The test report states that the BRE load tables only apply with the use of WO-60.

When the cement / polymeric resin powder component is mixed with the liquid component, it yields 3Lts of smooth and cohesive thixotropic masonry repair grout that is ideal for bonding helical reinforcement bars into masonry walls. This non-shrink masonry repair grout rapidly develops compressive strength. Advanced polymers improve adhesion and reduce the rate of water evaporation, allowing the crystal structure to keep growing and build strength.

The fully cured polymer-modified mortar has enhanced tensile strength, flexural strength, water resistance, and chemical resistance. Additionally, the polymer in the mortar helps restrain micro-crack propagation, which improves the overall toughness of the mortar

WHO 60 grout can be pumped and injected with a mortar gun or applied by trowel. It is supplied on pallets of 72 tubs

PRODUCT SPECIFICATION

TYPICAL PROPERTIES – WHO 60 Grout (BRE GBG62)

| Physical Properties | Strength |

|---|---|

| Compressive Strength – 7 days | 35N/mm² |

| Compressive – 28 days | 55N/mm² |

| Tensile Strength – 28 days | 5N/mm² |

| Flexural Strength – 28 days | 12N/mm² |

| Young’s modulus (fully cured) | 13kN/mm² |

TYPICAL PERFORMANCE LOADS 400mm bar-embedment length in WHO 60 Grout

| Bar Diameter |

Bars per Joint | Tension Load |

|---|---|---|

| 6mm | Single Bar | 8.39kN |

| 7mm | Single Bar | 9.75kN |

| 8mm | Single Bar | 11.06kN |

| 9mm | Single Bar | 11.50kN |

| 6mm | Double Bar | 16.00kN |

| 7mm | Double Bar | 17.65kN |

| 8mm | Double Bar | 17.65kN |

| 5mm | Triple Bar | 14.34kN |

Note: Single bars bedded 20mm deep: Double bars placed 15 & 25mm deep: Triple bars buried 10, 20 & 30mm deep. Height of the slot is at least 3mm greater than the diameter of the crack stitching bars. Depth of slot 35-40mm. All bars bonded in WHO 60 polymer-modified grout

TYPICAL PERFORMANCE LOADS for retrofit brick beams (taken from BRE Testing, including conservative factors of safety)

| Span |

Depth of Beam |

|||

|---|---|---|---|---|

|

||||

| 1.2m |

|

|||

| 1.6m |

|

|||

| 2.0m |

|

|||

| 2.4m |

|

|||

| 2.8m |

|

|||

| 3.2m |

|

|||

| 3.6m |

|

Brick beams were formed by installing two chords of double 6mm bar bedded in WHO 60 Grout. Bars extended 500mm on either side of the opening (span). The depth of the beam is the distance between each chord of double-helical bars. Loads are in kN/m run.