Replacing Cavity Wall Ties

Replacing cavity wall ties with a remedial tying system is a low-cost alternative to rebuilding walls suffering from wall tie corrosion. For 30 years, wall tie replacement has become the accepted method of solving and remedying cavity tie failure problems.

Wall tie failure generally occurs in one of two ways. There is either a lack of sufficient ties during construction or their deterioration due to rust. In the case of wall tie corrosion, the rusting steel builds iron oxide layers that expand. The degree of damage from expanding steel ties depends on the wall tie type used in construction.

- Ties produced from steel wire may erode and ultimately disintegrate. The result is a façade wall that is free-standing and vulnerable to wind loads.

- Ties manufactured from steel-strip tend to force the brickwork apart as they expand. The expansion force is irresistible and jacks the brickwork apart, causing cracks at tie positions. As more ties rust, a series of horizontal cracks can develop along the mortar bed joints that house the cavity ties. Such horizontal cracking significantly damages and weakens the structural integrity of the façade at a time when the eroding ties are less able to support it.

In either case, replacing cavity wall ties with a corrosion-resistant wall tie replacement system provides a robust and lasting remedial solution. Thor Helical manufactures a range of retrofit ties, these include:

Mechanical Helical Wall Ties

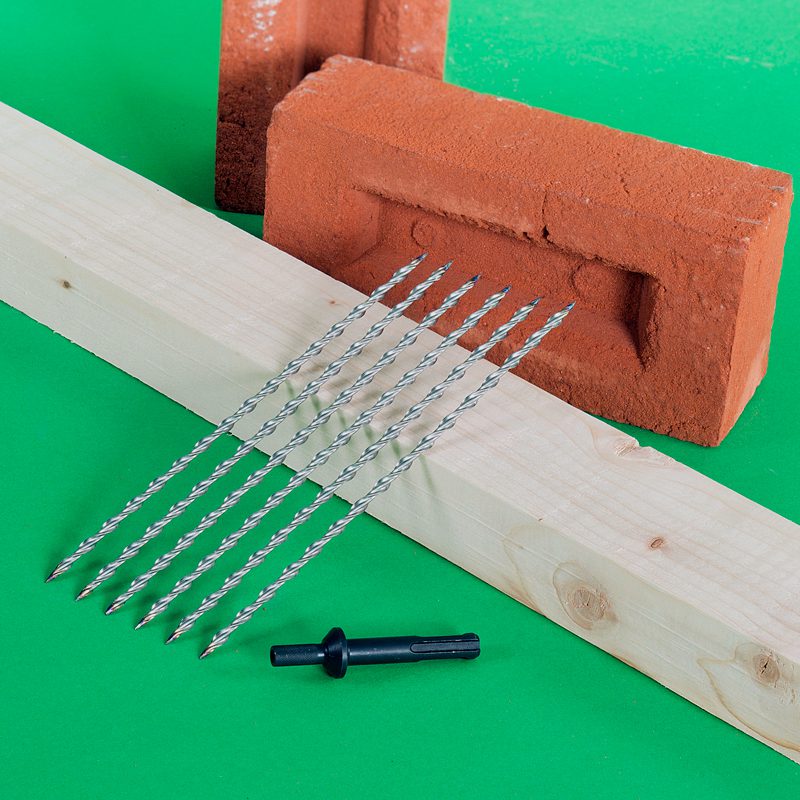

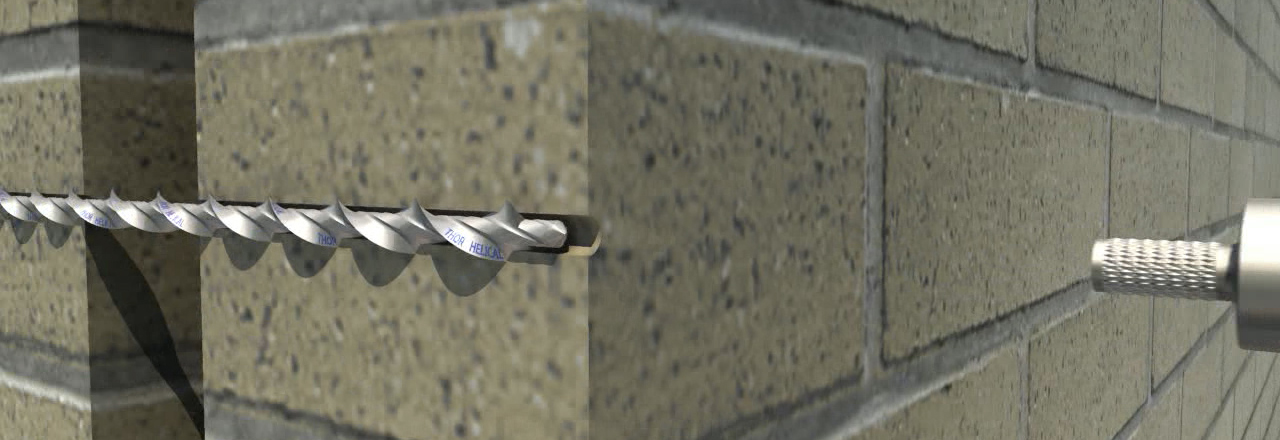

Thor helical’s one-piece stainless steel helical wall ties are 9mm in diameter. When the CD Ties are hammer-driven into small pilot holes, they corkscrew into brick, block and concrete, delivering a mechanical fix that grips the wall on each side of the cavity. Unlike ties having expanding mechanisms, which produce point-loadings when tightened, the twin-thread connection of the helical wall tie exerts no expansive stress into the brickwork and will not loosen with vibration.

Resin Fix Ties

Where the condition of masonry is poor, a resin-fix brick tie may offer a suitable fixing solution for replacing cavity wall ties. They are chemically bonded into small holes to connect or reconnect the walls on either side of the cavity. Resin fix ties are not appropriate where fire performance ratings exceed 30 minutes.

Resin/Mechanical Tie

Thor Helical timber frame ties are usually for use in new construction. However, they are also useful for replacing cavity wall ties in existing timber-framed houses up to 4 stories high. The flexible 5mm ties corkscrew as they are hammered through a 6mm clearance hole in the outer façade and onward into the wooden studs of the timber frame. The connection to the masonry wall requires a chemical bonding agent.

Our best-selling remedial wall tie is the Thor Helical CD Tie. The mechanical tie system is patented in four Continents and has a proven track record at out-performing every other helical wall tie on the market.

What makes the Thor Helical CD wall tie a cut above the rest?

- Suitable for use in brick, perforated brick, block, stone and concrete

- Ideal for replacing cavity wall ties in wide cavities of up to 225mm.

- Accommodates thermal, moisture and seismic movements.

- Resistant to fire and the transfer of water.

- Unique precise thread technology for unrivalled consistency and performance.

- Patented replacement wall tie system with a unique drive-shank

- Safe, easy to use and low cost SDS setting tool.

- CD ties conform to BS EN 845-1 in a broad range of substrates when tested to BS EN 845-6: 2012.

- Thor Helical CD wall ties meet the requirements for a Type 2 tie for cavity widths of up to 150mm (brick, block, perforated brick and concrete) and for a Type 3 for cavities of up to 225m wide (autoclaved aerated concrete).