Quick, easy to use and reliable fixings for composite insulation panels. These flat roof insulation fixings nail 6mm plywood-faced insulation boards to rafters in warm deck applications. They are supplied in stainless steel or zinc plated steel versions.

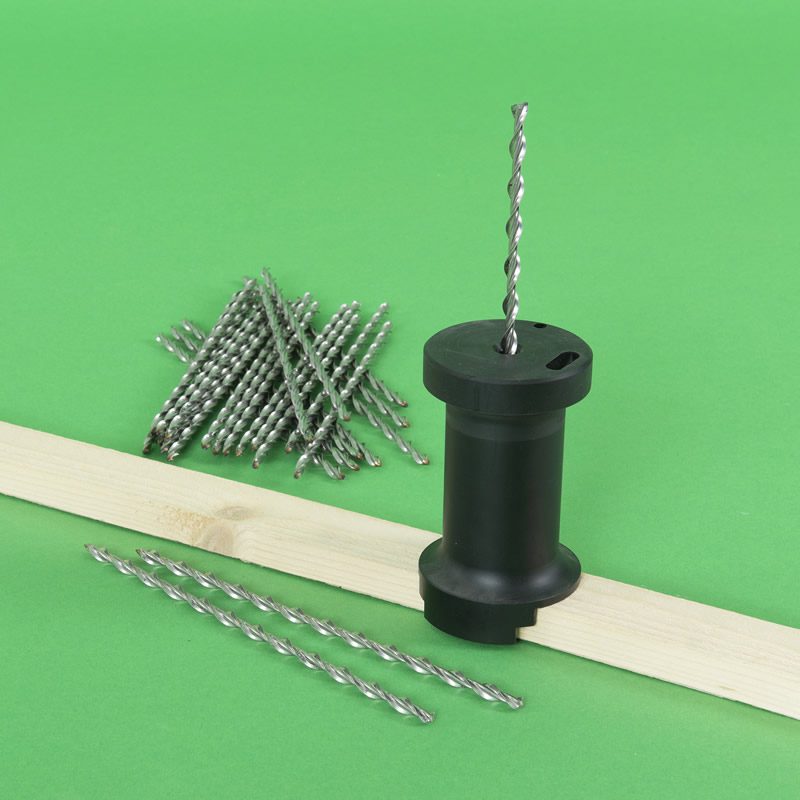

Flat Roof Insulation Fixings

Description

Thor Helical flat roof insulation fixings are generally used to fix 6mm plywood-faced composite insulation boards to softwood rafters in warm roof deck applications. Unlike traditional screws, the Insofast ISF-18 spiral fixings rotate as they are hammered in, inducing a self-tapping corkscrew action.

The quick, easy to use and reliable spiral nails have a large button head mounted on a precision engineered helical shank The cross sectional area of the profiled 7mm shank is just 10mm2. This small cross section reduces cold bridging by 75% when compared to a standard fixings of the same diameter.

Flat roof insulation fixings are available in zinc-plated carbon steel. For improved thermal performance, and additional protection against the corrosion, Thor Helical also supplies a stainless steel version. Stainless steel is 4 times less conductive than carbon steel.

These composite panel fixings supplied in lots of 2000. They are packed in boxes of 400 and resale bags of 20 pieces

The Thor Helical Insofast ISF-18 flat roof nails are available in a choice of zinc plated 8.8 high tensile steel or AISI304 stainless steel

Helical flat roof insulation fixings are available in standard lengths of:

- 120mm – for 80mm panels

- 145mm – for 85-110mm panels

- 170mm – for 115-135mm panels

- 195mm – for 140-160mm panels

- 220mm – for 165-185mm panels

- 245mm – for 190-210mm panels (stainless steel only)

CHARACTERISTIC PERFORMANCE LOAD (Tested at Ceram)

| Tension Test |

Load |

|---|---|

| 35mm Penetration in Softwood Joist | 1.25kN |

TYPICAL MECHANICAL PROPERTIES OF THOR HELICAL FLAT ROOF NAILS

| Stainless Steel |

Value |

|---|---|

| Ultimate Tensile Strength | => 11.0kN |

| Load at 0.2% Proof Stress | => 8.8kN |

| Zinc Plated Carbon Steel |

Value |

|---|---|

| Ultimate Tensile Strength | => 5.5kN |

| Load at 0.2% Proof Stress | => 4.9kN |

Text here…