Fire resistant mechanical fixings for insulated plasterboard, which ensure stability of boards in a fire. Can be used to compliment or replace plasterboard adhesives. Supplied in stainless steel or plated carbon steel

Mechanical Fixings for Insulated Plasterboard

Description

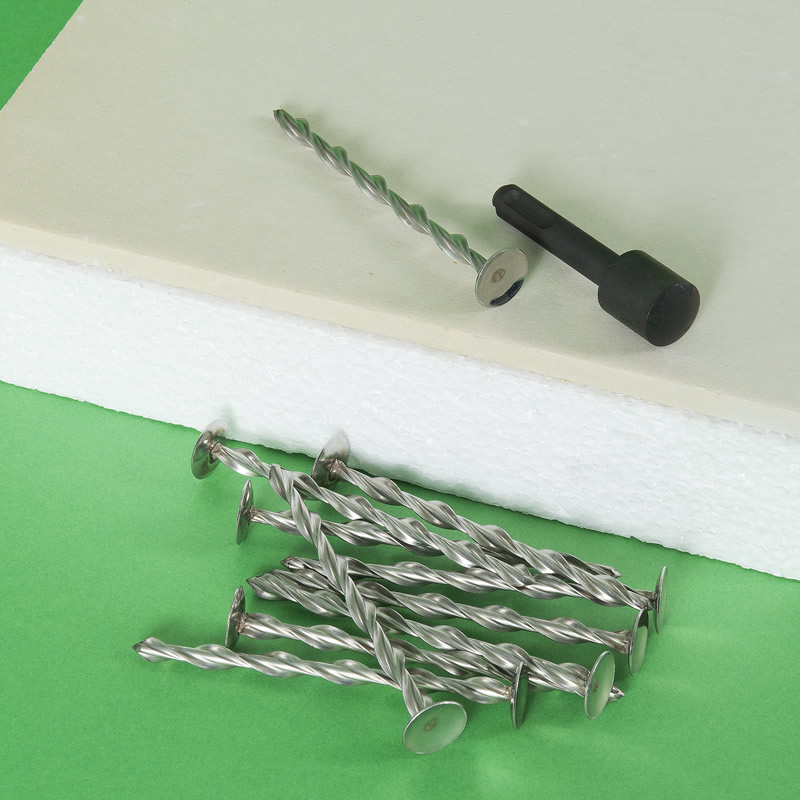

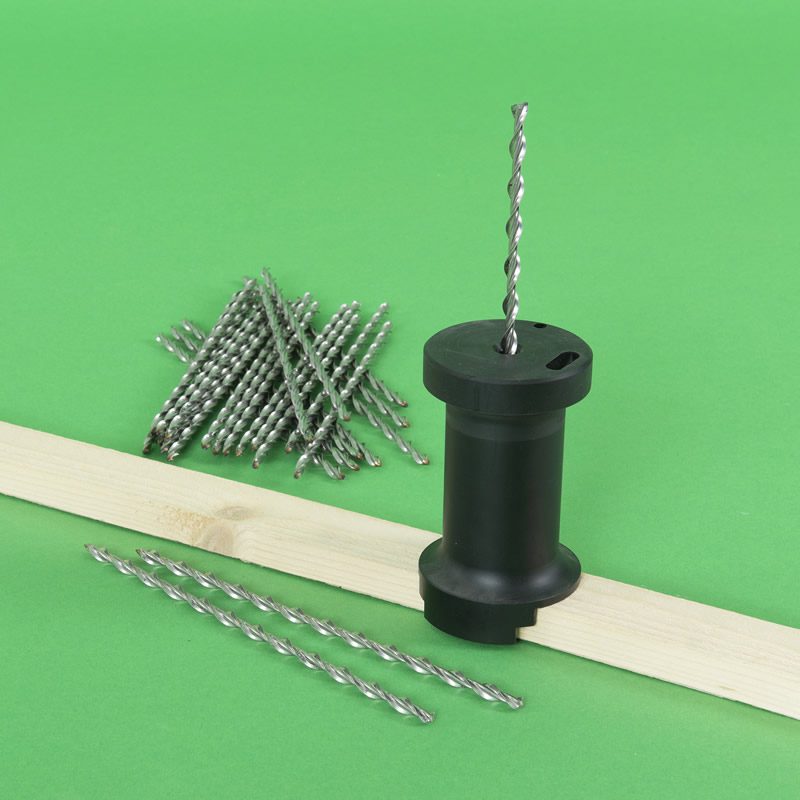

Thor Helical manufacture a range of fire resistant mechanical fixings for insulated plasterboard systems. They are suitable for fixing plasterboard backed with foam, polystyrene or mineral wool in solid internal wall insulation applications. The Insofast ISF-18A is a one piece fixing that has a large dish-profiled head mounted on a precision engineered helical shank.

The plasterboard fixings are suitable for use with all types of drywall boards. They can be used in conjunction with drywall adhesive (3 per board) or in place of it (12 to 18 per board). In both cases they ensure stability of the boards in the event of a fire and prevent plasterboard from falling on persons escaping a blazing building, or on persons entering a burning building for rescue purposes.

A 4mm to 5mm pilot hole is needed when fixing insulated panels to brick or block; the diameter dependent upon on the strength of the masonry. The fastener drives through plasterboard/insulation laminate and corkscrews directly into aerated gas concrete blocks or softwood without the need for a pilot hole. The concave dished head compresses the gyproc layer without tearing the paper surface, leaving a deep recess ready for accepting and retaining filler material.

Cold bridging is minimised thanks to a thermally efficient 7mm spiral shaft that has a cross sectional area just 10mm2. This small cross section reduces cold bridging by 75% when compared to a standard fixings of the same diameter. Mechanical fixings for insulated plasterboard are available in zinc-plated carbon steel. For improved thermal performance, and additional protection against corrosion, Thor Helical also supplies a stainless steel version. Stainless steel is 4 times less conductive than zinc plated carbon steel.

Insulated plasterboard fixings can be hammered into the pilot holes with a rubber mallet. Alternatively it can be installed using an SDS adaptor in a lightweight SDS drill set at slow speed and with rotary action disengaged.

These mechanical fixings are supplied in lots of 2000. They are packed in boxes of 400 and resale bags of 20 pieces.

PRODUCT SPECIFICATION

Mechanical fixings for insulated plasterboard are available in a choice of zinc plated 8.8 high tensile steel or AISI304 stainless steel

Insofast ISF-18A plasterboard fixings are available in standard lengths of:

- 65mm

- 85mm

- 105mm

- 125mm

- 145mm

- 170mm

PERFORMANCE LOADS

| Material/ Embedment | Pull Out | Pull Through |

|---|---|---|

| Aircrete / 60mm | 649N | N/A |

| Brick / 50mm | 622N | N/A |

| Softwood / 35mm | 681N | N/A |

| Plasterboard / 9.5mm | N/A | 255N |

| Plasterboard / 12.5mm | N/A | 340N |

TYPICAL MECHANICAL PROPERTIES OF THOR HELICAL DRYWALL FASTENERS

| Stainless Steel |

Value |

|---|---|

| Ultimate Tensile Strength | => 11.0kN |

| Load at 0.2% Proof Stress | => 8.8kN |

| Zinc Plated Carbon Steel |

Value |

|---|---|

| Ultimate Tensile Strength | => 5.5kN |

| Load at 0.2% Proof Stress | => 4.9kN |

Text here…