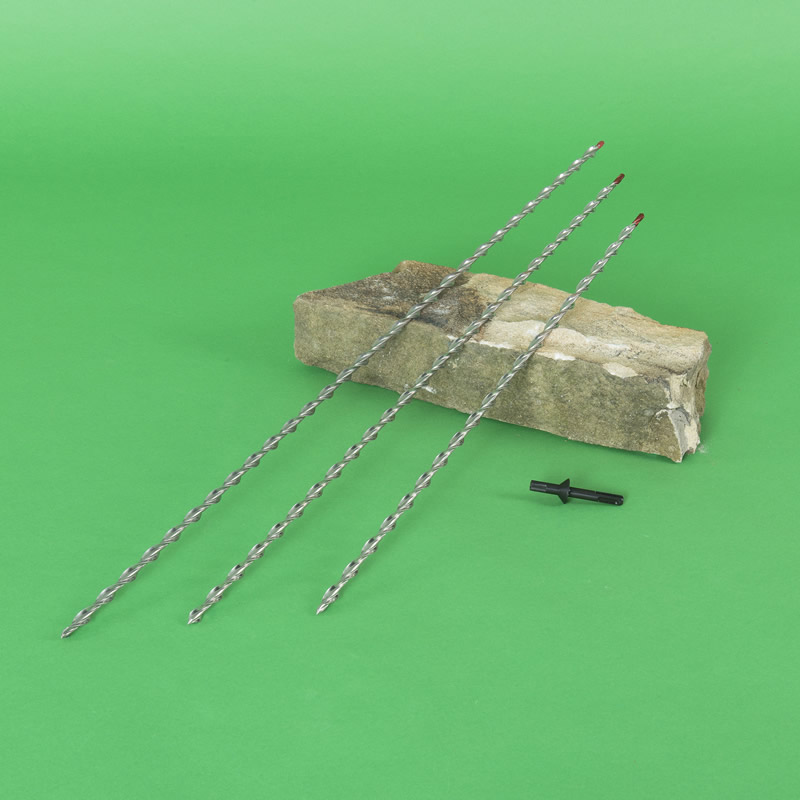

Helical strap ties are long-series 12mm CD ties that act as tension straps to connect the facade of a building to a wall that runs perpendicular to it. Installation of this lateral restraint system is at least ten times quicker to drill and fix compared with cement-grouted tying techniques. The tension tie is ideal for pinning masonry arches, quoins and thick rubble-filled walls and meets the requirements of EN 845-1 and conditions for UKCA and CE marking.

Strap Ties

Description

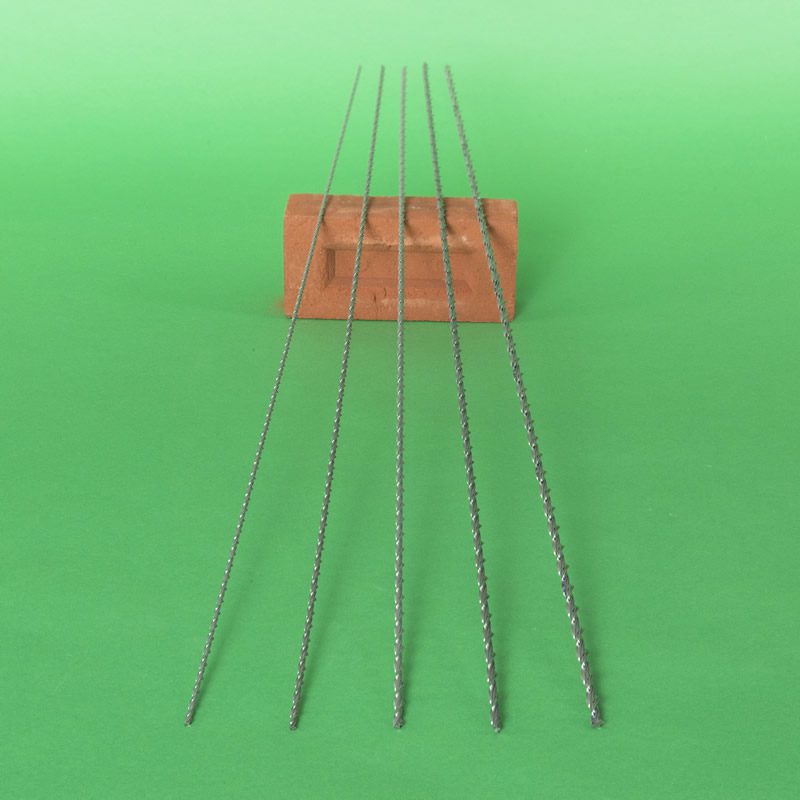

Helical strap ties are long-series spiral lateral restraint straps that secure the external wall to a wall that runs perpendicular to it. The 12mm diameter self-tapping wall ties are driven deep into masonry to form a mechanical connection that needs no cement, grout or resin, making them ideal for connecting walls on heritage houses, listed buildings and more modern constructions.

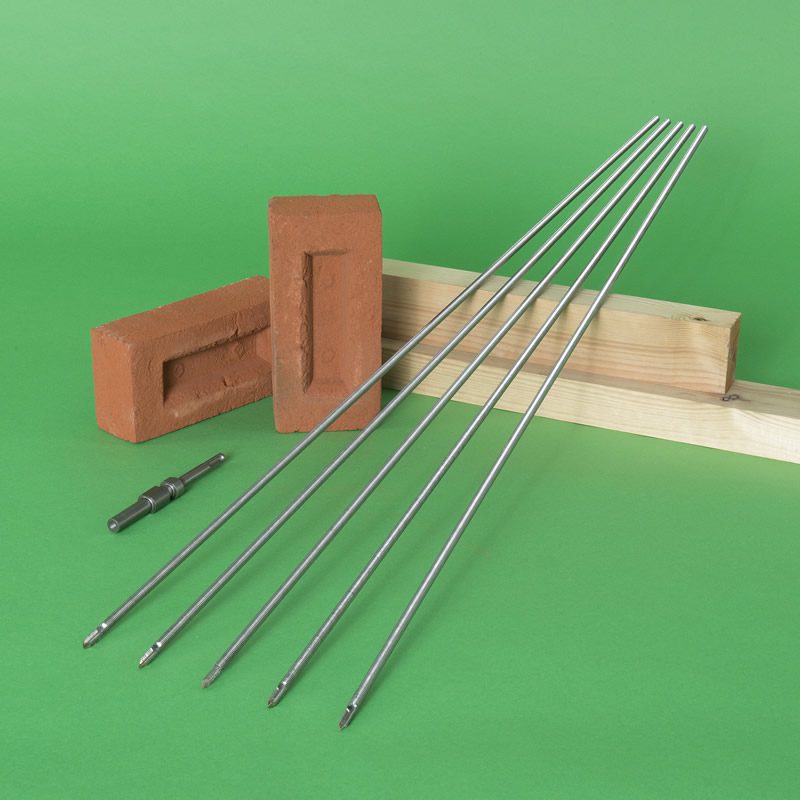

The heavy-duty 12mm diameter building ties are available in six standard lengths 610mm (24″), 760mm (30″), 910mm (36″) 1060mm (42″) 1220mm (48″) 1370mm (54″) 1520mm (60″) and 1670mm (66″); they have twice the strength of any other self-tapping helical wall ties of similar design. The connectors corkscrew into brick, block, limestone and concrete, when hammer-driven into a small pilot bore, to offer outstanding resistance to compression, tension and shear loads

The 316 marine grade stainless steel structural connectors have a cross-sectional area of more than 28mm2; they are ideal for pinning arches and re-connecting walls, such as at corners and party wall junctions, without the need for bonding agents. This feature eliminates issues of material compatibility that often arise with cement mortars in old or listed lime mortar buildings.

To install the Retrofit Strap Ties, drill the pilot holes and load the drive shank end of the fastener into the patented SDS drive-adaptor. Simply hammer the tie into the hole using the impact action of an SDS hammer drill.

The material cost of this heavy-duty 12mm spiral fixing system is similar to that of using traditional 8mm spiral bars with proprietary polymer-modified cement grout. However, it is at least 10 times faster to prepare and install, delivering exceptional savings in labour costs.

Applications for the Thor Helical 12mm Strap Ties include:

- Tying Facades to Party Walls

- Pinning Masonry Arches

- Securing Quoins

- Stitching Cracks at the Corner of a Wall

- Tying Thick or Rubble-filled Walls

- Providing Vertical Reinforcement to Parapet Walls

This patented retrofit lateral restraint strap system offers

- Less disturbance caused to buildings than with any other retrofit strapping system

- Longer and stronger than any other helical wall tie

- Ideal for use at any temperature, including sub-zero conditions

- No material compatibility issues on old historic buildings with lime mortars

- Cost-effective installation rates – 10 times quicker than grouted tie systems

PRODUCT SPECIFICATION

The Thor Helical 12mm ø CD Strap Tie is available in AISI316 grade Austenitic Stainless Steel. These lateral restraint strapping ties are supplied in standard lengths of:

- 610mm (24″)

- 760mm (30″)

- 910mm (36″)

- 1060mm (42″)

- 1220mm (48″)

- 1370mm (54″)

- 1520mm (60″)

- 1670mm (66″)

TYPICAL PERFORMANCE LOADS AT 215mm embedment (taken from CE Mark Testing)

BS EN 845-1:2013 National Annex NA states that the strap needs to provide equivalent performance to the prescriptive 30mm x 5mm lateral restraint straps, and the tension straps should have a declared tensile load capacity of at least 8kN.

| 12mm Tension Tie |

Load |

|---|---|

| Strapping Masonry to Masonry | 8.45kN |

TYPICAL MECHANICAL PROPERTIES OF THOR HELICAL STRAP TIES

| Product Attributes |

Value |

|---|---|

| Diameter | 12mm |

| CSA | 28mm2 |

| 0.2% Proof Stress | >820N/mm2 |

| Ultimate Tensile Strength* | 1025-1225N/mm2 |

| Mean Tensile Capacity # | 30kN |

* Ultimate Tensile Strength is measured within a calibrated tolerance of +/- 2%

# Mean Tensile Capacity is an indicative value derived from CSA x Mean UTS