Thin joint blockwork ties hammer directly into autoclaved aerated concrete blocks, providing a high speed and reliable connection. Suitable for all makes and strengths of aircrete and gas concrete and suitable for cavities up to 150mm wide. UKCA and CE Marked to BS EN 845-1

Thin Joint Wall Ties

Description

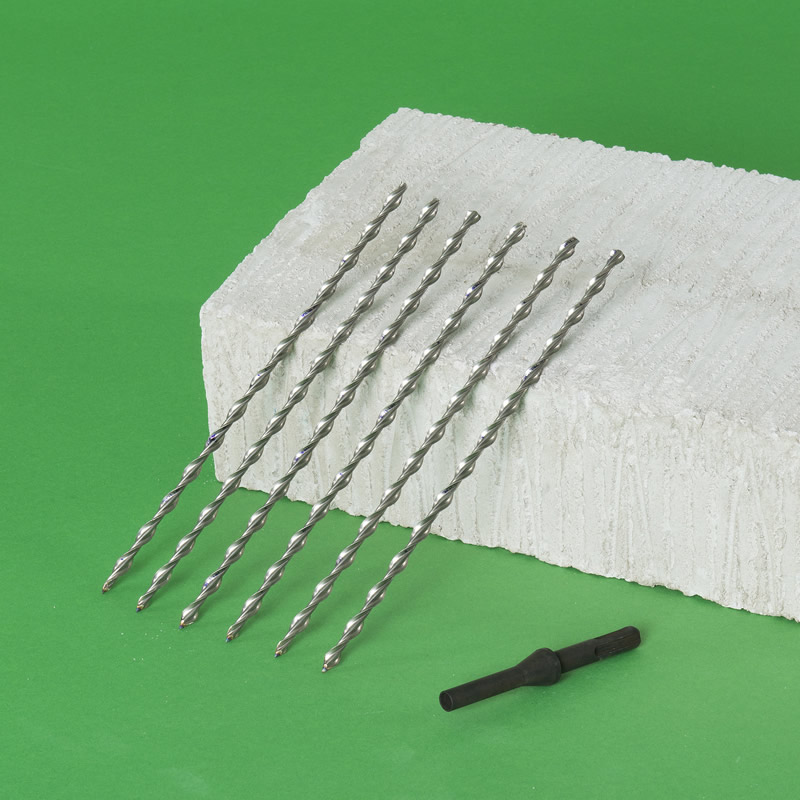

Thor Helical thin joint wall ties connect thin joint blockwork construction to an external facade. The thin-joint cavity wall ties are precision engineered; twist accuracy makes them the superior choice for fixing into Thermalite, Celcon, Xella, and similar gas aerated thermal blocks.

The helical wall ties are hammered directly into thin joint blocks to a depth of 85mm. Work hardened helical blades cut a precise interlocking thread into the host wall material, providing a high speed and reliable connection. Patented pitch accuracy ensures unrivalled performance in thermal blocks.

Thin joint wall ties are cold-roll profiled and twisted to form a 7mm diameter helical tie with a cross-sectional area of just 10mm2 and a nominal tensile strength of 11kN. The dynamic stiffness of the ties is less than 113MN/m3, taking both cavity width and tie density of 2.5 ties per square metre into account.

- Suitable for all makes and strengths of aircrete blocks – 2.8 to 10.5N/mm2

- Suitable for wide cavities – up to 150mm.

- Thor Helical thin joint wall ties conform to EN 845-1 and UKCA and CE marking conditions.

- The ties meet the requirements of PD 6697 as a type 2 or 3 tie; the classification is dependent on the strength of the block and the width of the cavity:

Thin joint ties are available in cartons of 2000 pieces or distributor-supplied boxes in bespoke quantities.

PRODUCT SPECIFICATION

The 7mm ø Thor Helical thin joint wall ties are AISI304 grade Austenitic Stainless Steel. Standard wall-tie lengths are:

- 205mm ties for 50mm cavity

- 230mm ties for 75mm cavity

- 255mm ties for 100mm cavity

- 280mm ties for 120mm cavity

- 305mm ties for 150mm cavity

TIE CLASSIFICATION

| Block Strength | 50 – 100mm Cavity | 125 – 150mm Cavity |

|---|---|---|

| 2.8 – 4.0 N/mm2 | Type 3 Tie | Type 3 Tie |

| 7.0 – 10.5 N/mm2 | Type 2 Tie | Type 3 Tie |

PERFORMANCE LOADS at 150mm cavity (taken from CE Mark Testing)

| Block Strength | Tension | Compression |

|---|---|---|

| 2.9N/mm² | 1410N | 930N |

| 3.5N/mm² | 1673N | 1346N |

| 7.0N/mm² | 1888N | 930N |

| 10.0N/mm² | 1856N | 930N |

PERFORMANCE LOADS at 100mm cavity (taken from CE Mark Testing)

| Block Strength | Tension | Compression |

|---|---|---|

| 2.9N/mm² | 1410N | 930N |

| 3.5N/mm² | 1673N | 1346N |

| 7.0N/mm² | 1888N | 1844N |

| 10.0N/mm² | 1856N | 1844N |

TYPICAL MECHANICAL PROPERTIES OF THOR HELICAL THIN JOINT TIES

| Product Attributes |

Value |

|---|---|

| Diameter | 7mm |

| CSA | 10mm2 |

| 0.2% Proof Stress | >880N/mm2 |

| Ultimate Tensile Strength* | 1025-1225N/mm2 |

| Mean Tensile Capacity # | 11kN |

* Ultimate Tensile Strength is measured within a calibrated tolerance of +/- 2%

# Mean Tensile Capacity is an indicative value derived from CSA x Mean UTS

For fixing Super-7 wall ties to thin joint blockwork you need a hammer or an SDS installing tool.